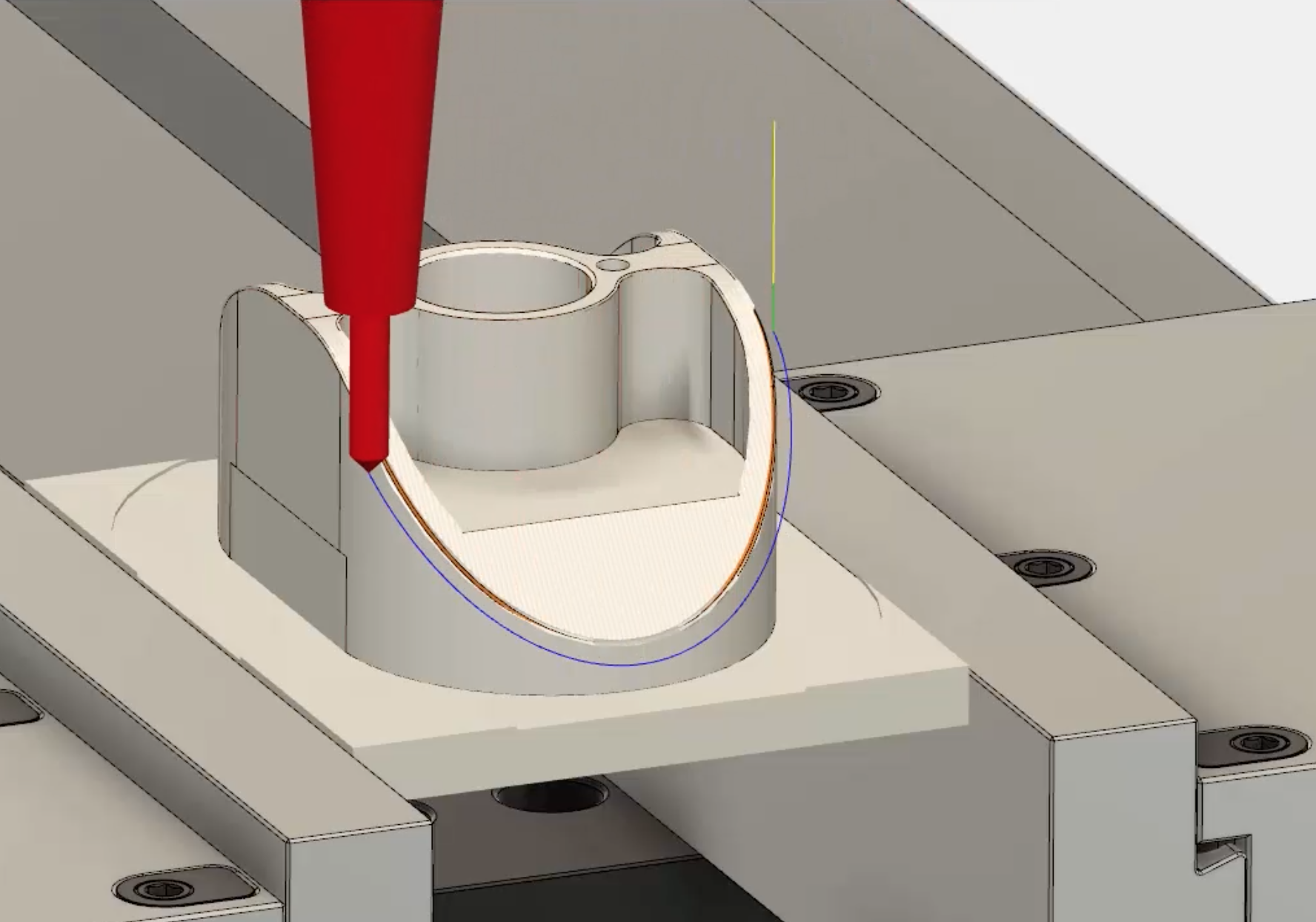

If you’ve secured your stock using screws, you can change the value up to the ones shown in the figure below (not less). I f you are using clamps to secure your stock to the spoilerboard, we advise you not to change these values. Editing this tab is optional, but you will eventually have to change these values when using long end mills or when milling really thick stock. The third menu tab is used to define planes above the model for the end mill to travel when it is not cutting. If this is an exterior contour, we have to use tabs so that, once the mill reaches the bottom of our piece, the whole body doesn’t come loose (which might be very dangerous).Ĭhange the tabs width, height and spacing until you feel the piece will be sufficiently supported but it won’t be a nightmare to clean after the milling is done. I n the second tab, select the contour you want to mill. In our example, we are going to choose an 8 mm flat end mill (from our End mill bundle ) for which we will use the hard wood preset. If you use a 2D operation instead of 3D on the conic hole for example, you’ll end up with a cylinder.Īs for any operations, you have to start by selecting the end mill you are willing to use for this operation. If what you want to mill is straight (in top view), then pick a 2D operation. Ĭhoosing between 2D or 3D operation is pretty straightforward: is the volume you want to mill a straight extruded shape, or is there any variance in the extrusion (chamfers, filets, bumps, gaps, slots, etc…)?

We recommend always using Adaptive Clearing over Pocket. This is especially true for hard materials like aluminium or hard plastics. The bigger the pocket you are willing to mill, the more time you will save by using Adaptive Clearing instead of Pocket.

Where Pocket cut constantly (and thus go faster than Adaptive Clearing ), the extra time your mill gets to cool down with the Adaptive Clearing allows it to handle bigger steps.

The main difference between both operations is that Pocket will keep a constant engagement of your mill in the stock, while Adaptive Clearing will take bites, alternating cutting and cooling.

W hen it comes to milling pockets (basically large holes), you have 2 options: the Pocket operation or the Adaptive Clearing operation.

0 kommentar(er)

0 kommentar(er)